EMIQ – Electronic Manufacturing Intelligence Quotient

An all-in-one data solution to increase your competitiveness in electronic components

Track daily pricing and inventory data from across the market

Monitor segment performance, inventory efficiency, and sales trends for competitors

Build robust pricing, acquisition, or entry strategies using data from over 1.2 million parts

The electronic component market, at your fingertips.

EMIQ’s value proposition for your business

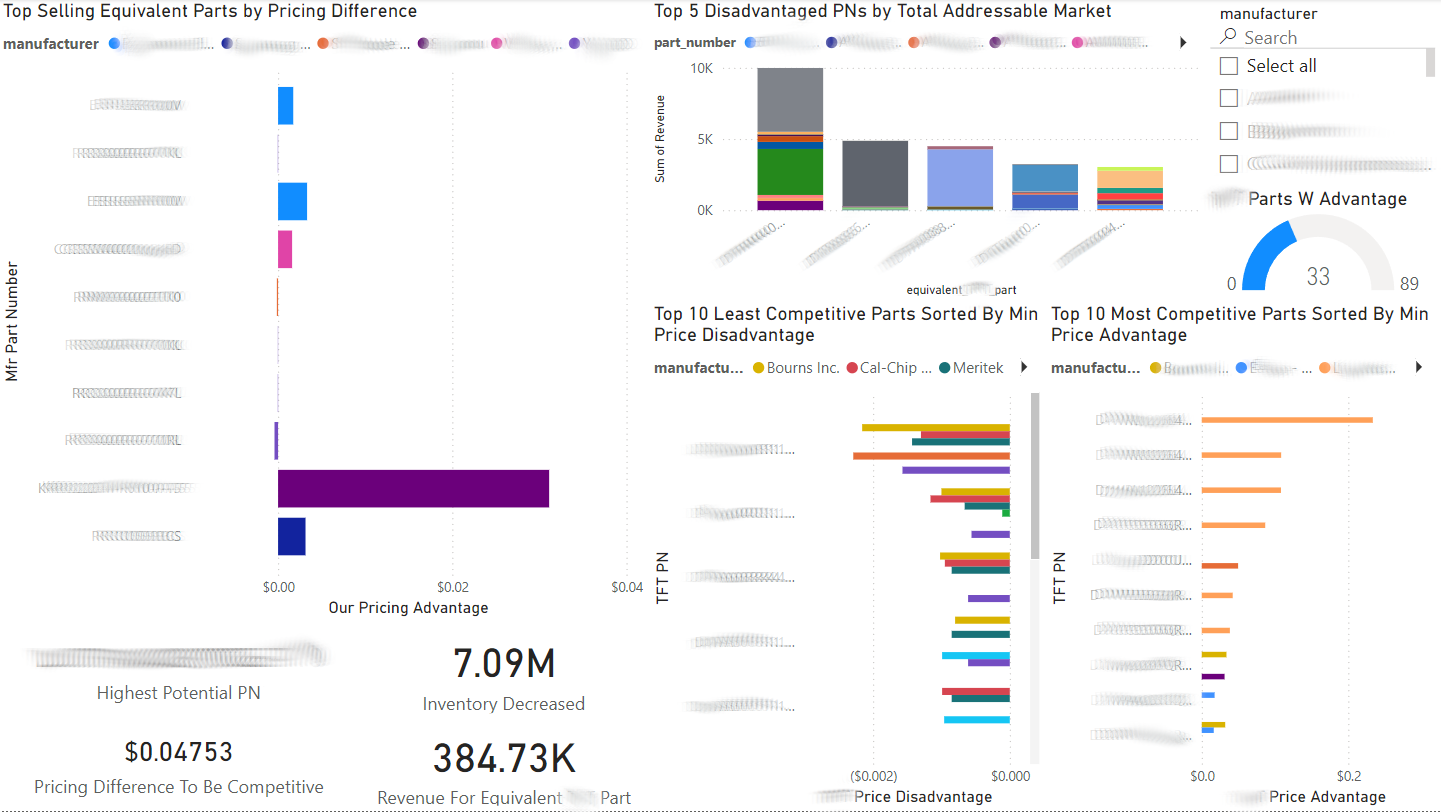

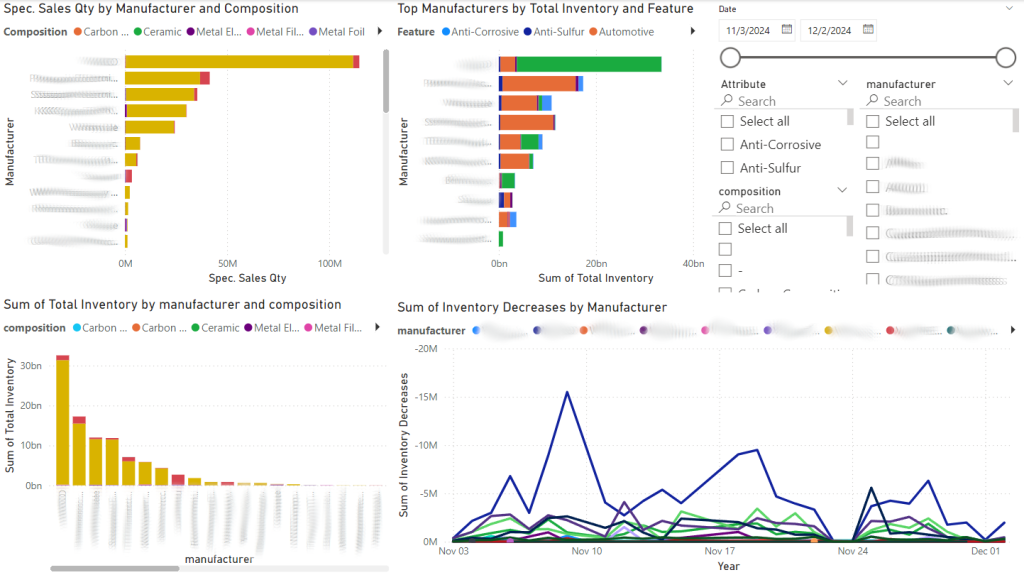

- Unparalleled Market Insights – Monitor the electronics supply chain and gain insights into inventory movements, pricing shifts, and sales trends from across the industry.

- Competitor Analysis – Stay ahead of the competition by watching how competing parts are performing and determine your ROI for crossing similar parts.

- Precise Data-Driven Decision Making – Empower your organization to make faster, smarter decisions by relying on EMIQ’s automated data ingestion and processing along with our data tools or your own.

EMIQ’s comprehensive suite of data and analytic services caters to the entire supply chain, from EMS acquisition managers to 3rd party electronic manufacturers.

- EMS company negotiates better supply terms

- Challenge: A global EMS company struggled with volatile pricing and fluctuating inventory availability for critical components, which disrupted production timelines and increased costs. Without detailed market intelligence, negotiations with suppliers were reactive rather than strategic.

- Solution: EMIQ was deployed to monitor supplier pricing changes, inventory turnover ratios, and inventory surpluses with dead stock.

- Results: EMIQ revealed surplus inventory among suppliers for key capacitors, creating an opportunity for negotiation on procurement.

- Benefits: By leveraging EMIQ’s insights, the EMS was able to negotiate a 15% price reduction on the bulk order of capacitors along building long term trust with a new supplier by using win-win agreements. Access to up to date information minimized last minute procurement challenges reducing lead times by up to 10%.

- Consulting firm identifies ROI for client’s entry into market

- Challenge: A small consulting firm was tasked with determining the ROI potential for a client’s new IoT decide targeting the industrial automation sector. Their client needed insights on pricing, sales potential, and production feasibility to determine the design’s profitability.

- Solution: Using EMIQ, the consulting company was able to create a component index for tracking pricing and inventory trends over time on the required parts.

- Results: Retrieving historical data for the cost of manufacturing and inventory movement allowed for predictive analysis on the potential costs and lead times for the new product which allowed a more narrow range for calculating costs.

- Benefits: The consultation company was not only able to develop a potential ROI for the product and it’s market share capture, but was also able to identify procurement strategies such as timing on bulk purchasing and identifying top suppliers.

Look through our case studies to determine if EMIQ is right for your organization.

- Electronic Manufacturer gaining market edge –

- Challenge: A mid-sized electronic manufacturer faced challenges in identifying which resistors to prioritize for production as market demand shifted. They were unable to keep up with competitor sales and pricing shifts which led to missed opportunities.

- Solution: By implementing EMIQ, the manufacturer was able to watch competitor sales, pricing shifts, and inventory fluctuations over time.

- Results: EMIQ identified the conditions for a surge in demand for 0603 anti-sulfur 10 mOhm chip resistors across the market, prompting the manufacturer to ramp up production of their offering.

- Benefits: Time to market decreased for the manufacturer as they were able to meet demand and capture a larger market share from their competitors – resulting in a 10% increase in revenue and securing long term customers.